Datetime:2025-06-11

In modern manufacturing, sheet metal processing and CNC processing are two mainstream metal forming technologies, and their core differences directly affect the selection strategy of industrial production. This article will start from the underlying logic of the process and systematically compare the technical characteristics of the two: sheet metal processing realizes the reconstruction of thin metal shapes through plastic deformation processes such as stamping and bending, while CNC processing relies on computer numerical control technology to drive the tool for precision cutting. Further analysis will reveal the significant differences between the two in terms of material thickness adaptability, surface treatment accuracy, equipment investment cost and batch production efficiency. At the same time, through the comparison of typical application scenarios, the advantages of sheet metal processing in box structure manufacturing and the irreplaceable nature of CNC processing in high-precision processing of complex parts are explained, providing engineering and technical personnel with a multi-dimensional technical selection basis.

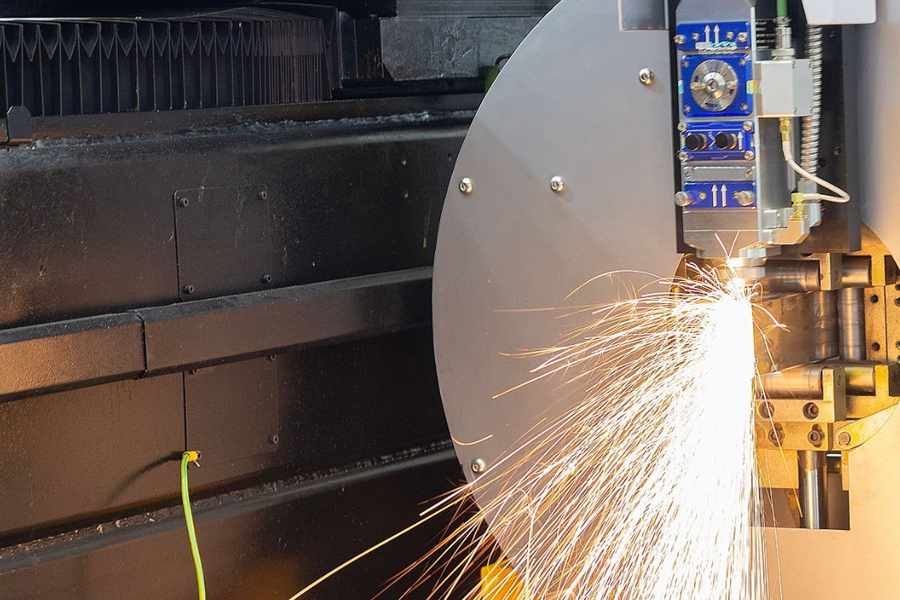

Differences in the process principles of sheet metal and CNC

There are essential differences between sheet metal processing and CNC processing at the process principle level. The core of sheet metal processing is to cause plastic deformation of metal sheets through external forces. The main processes include cutting, bending, stamping, etc. Its essence is to achieve part forming by changing the geometric form of the material. For example, the bending process applies pressure to the sheet through the die to form a specific angle, while stamping uses the cooperation of the punch and the die to achieve contour forming. In contrast, CNC machining (computer numerical control machining) is based on the principle of subtractive manufacturing. It drives the tool to cut, drill or mill the workpiece through the CNC program to gradually remove the material to achieve the target shape. Its processing process relies on the coordinate control of the high-precision CNC system, and the processing of complex three-dimensional structures is achieved through tool path planning. From the perspective of energy transfer, sheet metal processing mainly drives material deformation by mechanical energy, while CNC machining achieves material cutting and separation through kinetic energy conversion. This difference in the nature of the process directly leads to significant differences in processing flexibility, surface treatment methods and the degree of retention of physical properties.

Comparison of material adaptability and processing accuracy

In terms of material applicability, sheet metal processing mainly targets plastic deformation of metal sheets. Its advantages are reflected in its efficient processing capabilities for thin plate materials (usually ≤6mm thick) such as low-carbon steel, stainless steel and aluminum alloy, especially in processes such as bending and stamping. In comparison, CNC machining can be compatible with a wider range of material types through cutting and forming technology, including solid blanks such as castings, forgings and engineering plastics, and has less restrictions on material thickness. In terms of precision, sheet metal processing is affected by factors such as mold gap and springback effect, and the conventional precision range is ±0.1mm to ±0.3mm, which is suitable for structural parts with medium tolerance requirements; while CNC machining relies on multi-axis linkage and precision tool system to achieve ±0.02mm or even higher processing accuracy, which is especially suitable for the forming needs of precision parts and complex surfaces. It is worth noting that the difference in accuracy between the two is closely related to the characteristics of the equipment, which provides a key basis for the selection of subsequent application scenarios.

Analysis of equipment characteristics and application scenarios

Sheet metal processing equipment is centered on bending machines, punching machines, and laser cutting machines. It realizes the forming of metal sheets through shearing, stamping, bending and other processes. Its equipment structure is compact and is mostly suitable for rapid processing of thin plate materials (thickness is usually ≤6mm). This type of equipment shows high efficiency advantages in the production of standardized structural parts such as electrical cabinets, chassis shells, ventilation ducts, etc., and is especially suitable for mass manufacturing in the fields of home appliances and communication equipment. In contrast, CNC machining centers (such as CNC milling machines and lathes) rely on multi-axis linkage systems and precision tools to perform three-dimensional cutting of metal blocks with a machining accuracy of ±0.01mm, which is suitable for small-batch customized production of complex curved parts (such as mold cavities and aerospace precision parts). It is worth noting that sheet metal processing equipment usually has the ability to integrate modular production lines, while CNC equipment emphasizes the process coverage of single-machine processing. In the selection of application scenarios, sheet metal processes are mostly used for shell products that emphasize structural strength and lightweight, while CNC technology is more inclined to the manufacture of precision parts with high precision and complex geometric features.

Cost efficiency and industrial selection points

In manufacturing decisions, cost efficiency and process adaptability directly affect production benefits. Sheet metal processing is usually suitable for mass production of thin plate workpieces. Although its mold development cost is relatively high in the early stage, the processing cost of a single piece decreases significantly with the increase in output, especially for standardized boxes, brackets and shell products. The material utilization rate can reach more than 85%, which has the advantage of economies of scale. CNC machining uses a digital cutting mode, does not require special molds, and has a relatively stable processing cost per piece. It is more suitable for the production of small batches and multiple varieties of complex parts, such as precision instrument parts or special-shaped structural parts. Its advantage of processing cycle flexibility is particularly prominent in customized scenarios. From the perspective of equipment investment, sheet metal production lines need to be equipped with multiple equipment such as shearing machines, bending machines and punching machines. The initial investment threshold is low but the land demand is large; CNC machine tools are highly integrated, but the purchase and maintenance costs of high-end five-axis systems are significantly increased. When selecting industrial models, it is necessary to comprehensively consider the order size, part complexity and delivery cycle - products with stable batches and simple structures are preferred for sheet metal processes, while complex parts with high precision and multi-process integration tend to be CNC solutions.

From the previous comparison, it can be seen that the essential difference between sheet metal processing and CNC processing stems from the fundamental difference in forming methods and process goals. The sheet metal process achieves efficient forming of thin plate structures through cold working deformation such as stamping and bending. Its core advantage lies in the rapid construction of lightweight shells or frame-type components; while CNC machining relies on the cutting movement of precision tools to remove materials layer by layer, and is more suitable for the manufacture of complex geometric shapes or high-precision functional parts. In actual applications, the two are not in a competitive relationship, but complement each other based on product demand: sheet metal processing has significant cost advantages in the mass production of thin-walled parts, while CNC machining provides technical support for small batches of highly complex parts. When selecting a process, companies need to comprehensively consider key parameters such as production scale, precision requirements, material thickness and structural characteristics, and establish a manufacturing plan that meets economic benefits and technical feasibility.