BACK

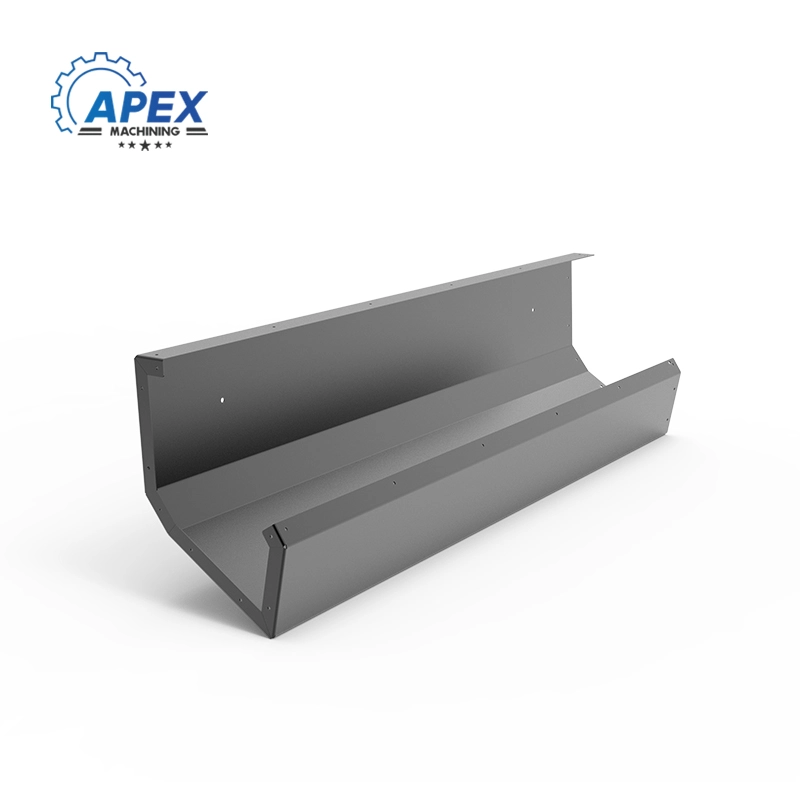

Automobile accessories-car skin

Automobile skin is an important part of automobile appearance, and material selection, cutting and forming process is the key to production. Aluminum alloy material light weight, high strength, strong corrosion resistance, plating steel plate excellent rust resistance, good formability. Precision cutting ensures design specifications, laser cutting flatness is high, hot forming process plasticity is good, and welding process is stable.

As an important part of the appearance of the car, the car skin not only affects the overall beauty of the vehicle, but also plays a key role in the aerodynamic performance and safety of the vehicle. Our automotive skin production technology is exquisite, committed to creating high-quality, high-performance automotive skin products for customers.

Select materials to lay the foundation for quality

The material selection of automobile skin is extremely sophisticated. We mainly use high strength aluminum alloy and high quality galvanized steel sheet. Aluminum alloy material has the characteristics of light weight, high strength and strong corrosion resistance, which can effectively reduce the weight of the body, improve the fuel economy, and ensure that the skin is not easy to deformation in long-term use. Galvanized steel plate with excellent rust resistance and good formability, for the skin to provide reliable quality assurance. In the material selection process, each batch of raw materials is subjected to rigorous quality testing to ensure that its performance indicators meet the high standards of the automotive industry.

Precise cutting, fit the design specifications

According to the complex design shape of the automotive skin, we use advanced laser cutting technology for precise cutting. Laser cutting can cut various shapes of skin plates with extremely high precision, smooth incision, no deformation, and can accurately meet the size requirements of design drawings. For some irregularly shaped skin parts, such as the outer skin of the door, the hood, etc., the advantages of laser cutting are particularly obvious, which can ensure the cutting quality at the same time, minimize material waste, and provide accurate billets for the subsequent molding process.

Innovative molding, creating a perfect appearance

Molding process is the core of automobile skin production. For a large area of flat skin, we use high-precision CNC stamping technology, through the precise stamping of the mold, the sheet rapid molding into the required flat shape, to ensure the flatness and dimensional accuracy of the skin surface. For the parts with complex curved surfaces, such as the roof and the arc of the side of the body, advanced thermoforming processes are used. In the high temperature environment, the sheet becomes more plastic, and through the pressing of special molds, complex curved shapes can be accurately shaped to fit the streamlined design of the car and improve the aerodynamic performance of the vehicle.

Precision welding to ensure a stable structure

Advanced resistance spot welding and laser welding technology are used for the connection between the various parts of the automobile skin. The resistance spot welding can effectively control the heat influence range of the welding area and reduce the deformation of the plate while ensuring the welding strength. For some parts that require very high appearance quality, such as the splicing of the body surface, laser welding plays an important role. Laser welding can achieve high-quality seamless welding, beautiful weld and high strength, not only improve the overall strength and structural stability of the automotive skin, but also provide a good foundation for the subsequent painting process.

Fine coating, improve protection and beauty

Painting is the last important process of automobile skin production. We use advanced electrophoretic coating and multi-layer spray-painting processes. Electrophoretic coating can form a uniform and dense primer protective film on the skin surface, which can effectively improve the anti-rust and anti-corrosion ability of the skin. On this basis, multi-layer painting, the selection of high-quality automotive special paint, through the precise spraying process, so that the paint surface uniform coverage, bright color, lasting. Finally, after high-temperature baking and curing, a hard, wear-resistant paint is formed, which not only adds a bright appearance to the car skin, but also further improves its protective performance.

Our automotive skin production process, from material selection to painting, every link is strictly controlled, committed to providing customers with high-quality, beautiful and durable automotive skin products, to help car manufacturers to create more attractive and quality automotive products.