BACK

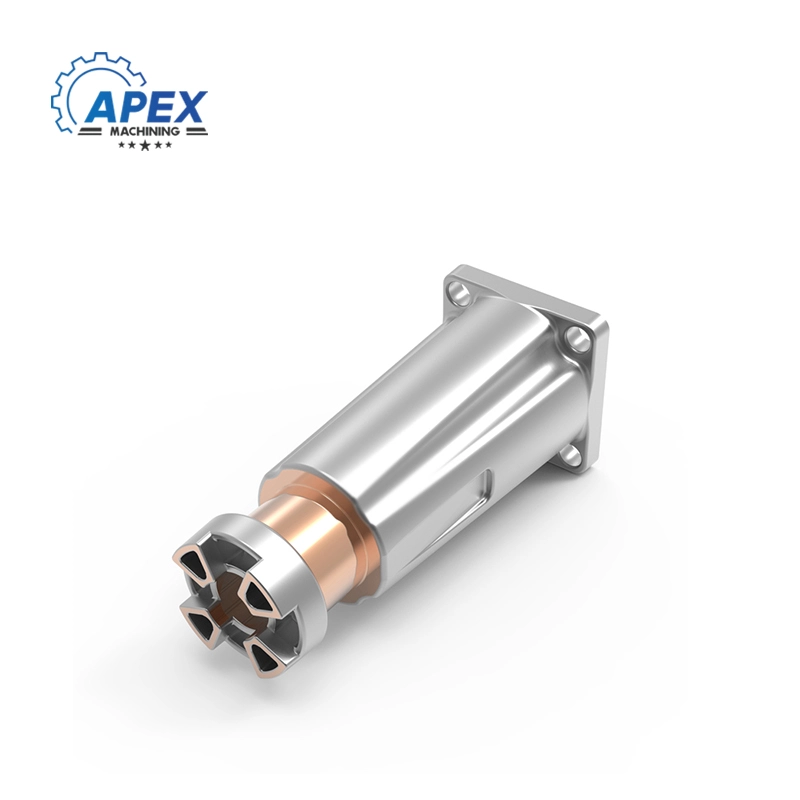

Bearing seat for lifting rod

Lifting rod bearing seat, CNC precision manufacturing, provides support for the lifting rod, and plays a key role in many fields.

An absolutely essential part of the lifting rod's working mechanism is the bearing seat. CNC machining painstakingly produces it to satisfy high accuracy and dependability criteria.

A mechanical construction intended especially to support and set the bearings connected to the lifting rod forms the bearing seat of the lifting rod. Usually composed of premium metal resources, including stainless steel or high-strength alloy steel, CNC machining allows one to precisely shape forms and sizes that satisfy design requirements. Its look usually shows a block or shell construction with a certain thickness and strength, with exact bearing mounting points inside. These mounting places have very low dimensional tolerances, which guarantees precise and strong embedment of the bearings in them.

Its importance is really great. First, it offers a sturdy and appropriate installation environment for the bearing so that it may keep excellent concentricity and verticality throughout running. This guarantees the smooth functioning of the whole lifting rod system, helps to lower bearing friction and wear, and thus increase bearing service life. The bearing seat of a lifting rod carries forces from all directions, including axial force, radial force and impact force generated by lifting action. Its robust construction and outstanding mechanical qualities help to efficiently distribute and transfer these forces, therefore preventing unequal force damage to the bearing.

Many different fields find great use for the lifting rod's bearing seat. In construction engineering, it supports material hoists and other equipment as well as the lifting rods of many lifting construction platforms. Regarding stage equipment, numerous stage lifting devices depend on bearing seats to guarantee the steady running of the lifting rod and achieve adaptable modifications of stage sceneries. The bearing seat is crucial for various unique vehicles, including the ladder raising system of fire trucks and the lifting mechanism of the working platform of aerial work vehicles, to guarantee the safety and dependability of the vehicle while doing jobs. In the sphere of communications, several liftable communication towers or antenna poles utilize it for lifting mechanisms to guarantee that the communication equipment may run stably at a sufficient height and guarantee excellent signal transmissions.

CNC machining produces very accurate and dependable manufacturing of the lifting rod's bearing seat. In many different areas including construction, stage, vehicle, and communication, it performs an essential and significant part in the lifting rod systems because of its robust structure, strong mechanical qualities, and efficient support and protection for bearings. It is among the fundamental parts making sure lifting machinery runs normally, safely, and effectively.