BACK

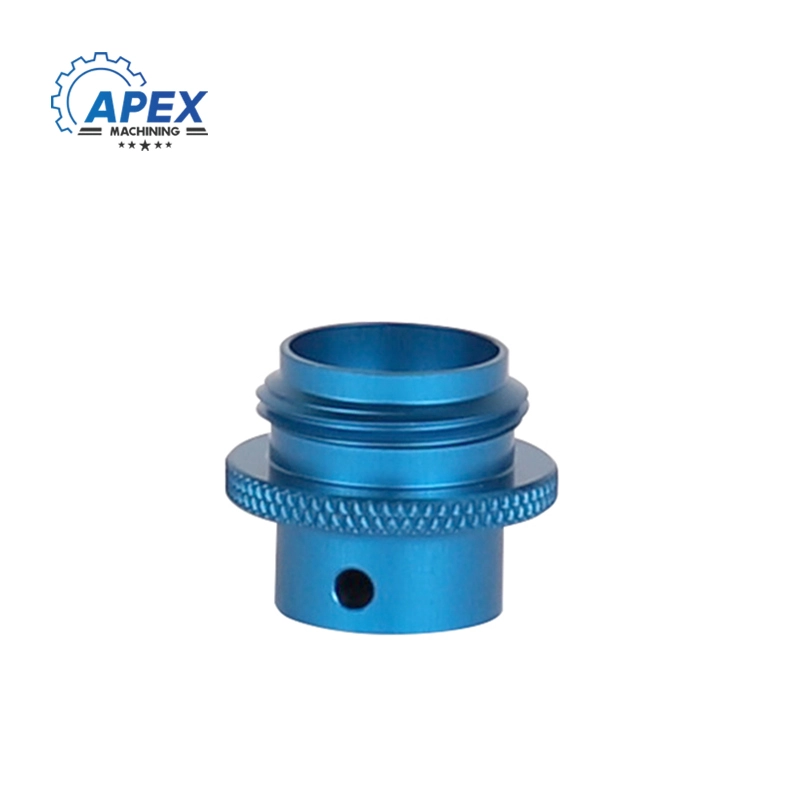

Blue anodized parts

Blue anodized - CNC processed aluminum alloy, high precision, corrosion resistance and beauty, stable operation in medical diagnosis equipment, relying on excellent process, strong function and image.

Within the sphere of medical diagnostic tools, component standards are rather strict. They must not only satisfy certain practical and aesthetic needs but also possess great stability and accuracy. Unique process qualities of blue anodized - CNC processed aluminum alloy items are drawing attention.

CNC machining (CNC) initially finely shapes the aluminum alloy output. High degree of automation and accuracy of CNC machining are well-known. By precisely managing the tool's motion trajectory, cutting speed and depth using computer programming, it can transform aluminum alloy raw materials into many intricate and exact forms. Whether it is a precise connection structure, a unique groove design, or a small aperture size, it can be precisely presented in the CNC machining process, so guaranteeing close fit and accurate docking between components, so ensuring the stability of equipment operation and the accuracy of data collecting. This guarantees a solid and reliable basic component for the overall architecture of medical diagnosis equipment.

The blue anodizing technique gives the product even more special value. In the medical environment, anodizing forms a dense oxide film on the surface of aluminum alloy that not only greatly increases the hardness, wear resistance, and corrosion resistance of aluminum alloy but also helps it to resist the erosion and physical wear of many chemicals for a long period, so extending the service life of the product. More significantly, the blue anodizing process provides the product a lovely and distinctive look. In medical equipment, this blue tone usually results in a peaceful and professional visual experience. It also helps to differentiate various components or functional regions, provide medical operators less difficult visual direction, and somewhat increase the accuracy and convenience of operation.

Blue anodized-CNC processed aluminum alloy products are indispensable in medical diagnostic tools, including critical structural components of imaging equipment and high-precision testing tools. Its stable physical characteristics guarantee that the equipment can still have accurate diagnosis functions under regular use and complex surroundings; the great appearance design improves the whole quality image of the equipment, so bringing patients and medical staff a more dependable and professional psychological feeling.

Blue anodized-CNC processed aluminum alloy goods basically accomplish high-precision molding with their superior CNC processing technology, and with the assistance of blue anodizing technology they achieve outstanding surface performance and aesthetic effects. It has become a premium option in the sphere of medical diagnosis tools and accessories; it has greatly supported the ongoing advancement of medical diagnostics technology and has helped to safeguard human health by means of its protection.03