BACK

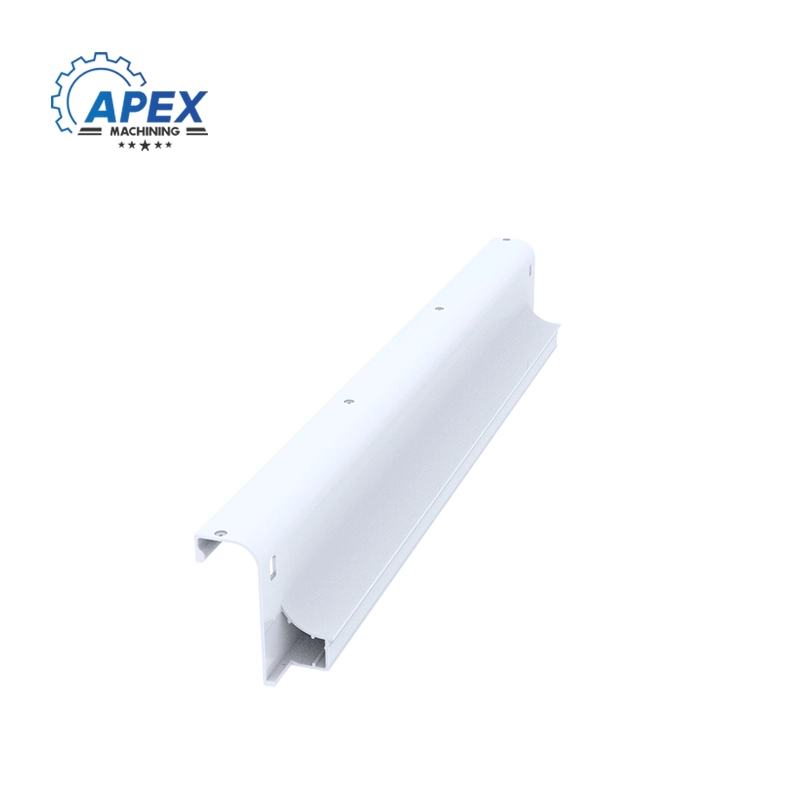

Centrifuge Handle Seat CNC Manufacture

Large centrifuge handle seat, CNC precision, high-quality materials, ergonomic design, stable installation and connection, help the centrifuge run accurately.

Large centrifuges are essential in many experimental disciplines, with their strong centrifugal force among the many families of laboratory tools and equipment. Using sophisticated CNC machining technology, the handle seat of big centrifuges demonstrates great quality and performance as a necessary component.

Using CNC machining technology, this big centrifuge handle seat guarantees perfect detail precision. The CNC system precisely regulates the direction, speed, and cutting depth of the tool depending on the preset program throughout the machining process so that the outside shape, aperture size, and connection elements of the handle seat may satisfy rather high accuracy criteria. For instance, the mounting hole on the handle seat for connecting the centrifuge body has a tolerance control inside a very small range, which guarantees a tight and stable combination with the centrifuge and prevents loosening or shaking during high-speed rotation, so providing a strong assurance for the safety of experimental operations.

Regarding materials, we use very strong, wear-resistant, stable metal ones. Apart from withstanding the great centrifugal force and vibration produced by the centrifuge operation, this substance possesses great corrosion resistance. It can keep structural integrity and performance stability even in the long run in the complicated chemical environment of the laboratory. Its strong features help the handle seat to provide operators a consistent grip, thus facilitating the performance of many centrifuge operations like starting, halting, and speed adjustment.

Design-wise, ergonomic ideas are given whole attention. The handle seat's form suits human hands' gripping patterns, and the surface is especially treated to give a pleasant touch and lower weariness resulting from long-term operation. Its general structural arrangement is sensible concurrently. It maximizes space use to the furthest degree, guarantees synchronization with other sections of the centrifuge, and provides complete play for the general performance of the centrifuge without changing its general look and operation.

The handle seat of big centrifuges is very important for their functioning. Acting as an interaction center between the operator and the centrifuge, it has to not only guarantee its own dependability and strength, but also be able to faithfully convey operational directions. Strong support for the stable operation of the centrifuge is given by the handle seat produced by CNC machining technology, which can be stably installed on the centrifuge and remains unchanged under high-intensity centrifugal force, so guaranteeing the accuracy and dependability of experimental data.

Due to the great accuracy of CNC processing technology, the great strength and stability of high-quality metal materials, and the comfort of ergonomic design, the handle seat of big centrifuges has become, in essence, a necessary important accessory for them. It guarantees experimental safety, enhances operational convenience, guarantees the correctness of experimental data, and helps laboratory apparatus and equipment to be run effectively.