Datetime:2024-12-21

In modern industrial production, automatic machining technology plays a vital role. Among them, the process from precision CNC stamping to bending has shown strong strength and wide application prospects in many fields.

Precision numerical control stamping is a kind of metal sheet stamping process by using numerical control technology to control the punch. It has the advantages of high precision, high efficiency, high repeatability, etc., and can quickly and accurately produce various metal parts with complex shapes.

The working principle of precision CNC stamping is to control the movement of the slider through the CNC system, so that the stamping die installed on the slider is pressed on the metal plate placed on the workbench. The shape and size of the die determine the shape and size of the stamping part. During the stamping process, the press pressure and speed can be adjusted according to different material and part requirements to ensure stamping quality and efficiency.

Advantages and characteristics

Application field

Precision CNC stamping is widely used in automobile manufacturing, electronic appliances, aerospace and other fields. In automobile manufacturing, stamping process can produce parts such as body shell, engine hood, door, etc. In the field of electronic and electrical appliances, stamping process can produce a variety of shell, radiator and other parts; In the aerospace field, the stamping process can produce aircraft fuselages, engine blades and other parts.

Bending technology

Bending is the process of bending sheet metal to a certain Angle or shape through pressure. The bending process is usually performed after stamping to further process the stamped part to meet specific design requirements.

The working principle of the bending process is to apply pressure to the sheet metal through the bending machine to bend it into the desired Angle or shape under the action of the mold. The bending machine is usually composed of a workbench, a bending die, a pressure system, etc. In the bending process, the shape and size of the bending die determine the Angle and shape of the bending part, and the pressure system provides the required pressure to make the sheet metal plastic deformation.

Advantages and characteristics

Application field

Bending technology is widely used in machinery manufacturing, architectural decoration, furniture manufacturing and other fields. In machinery manufacturing, bending process can produce various mechanical parts, frames, etc. In the field of architectural decoration, bending process can produce a variety of metal decorative parts, doors and Windows; In furniture manufacturing, the bending process can produce a variety of metal furniture parts, frames, etc.

From precision CNC stamping to bending process connection

The process connection from precision CNC stamping to bending is a complex and critical process. In this process, several factors need to be considered to ensure that high-quality parts are produced.

In the design stage, it is necessary to consider the process requirements of stamping and bending, and reasonably design the shape and size of the parts. For example, when designing stamping parts, it is necessary to consider the position and Angle of bending to avoid the situation that cannot be bent or affects the performance of the part after bending.

Stamping and bending require the use of molds, mold design and manufacturing quality directly affect the quality of parts and production efficiency. In the mold design process, it is necessary to consider the strength, precision, wear resistance and other factors of the mold to ensure that the mold can meet the production requirements.

In the production process, it is necessary to strictly control the process parameters of stamping and bending, such as pressure, speed, Angle, etc. At the same time, it is also necessary to carry out real-time monitoring of the production process, discover and solve problems in time, and ensure the smooth progress of production.

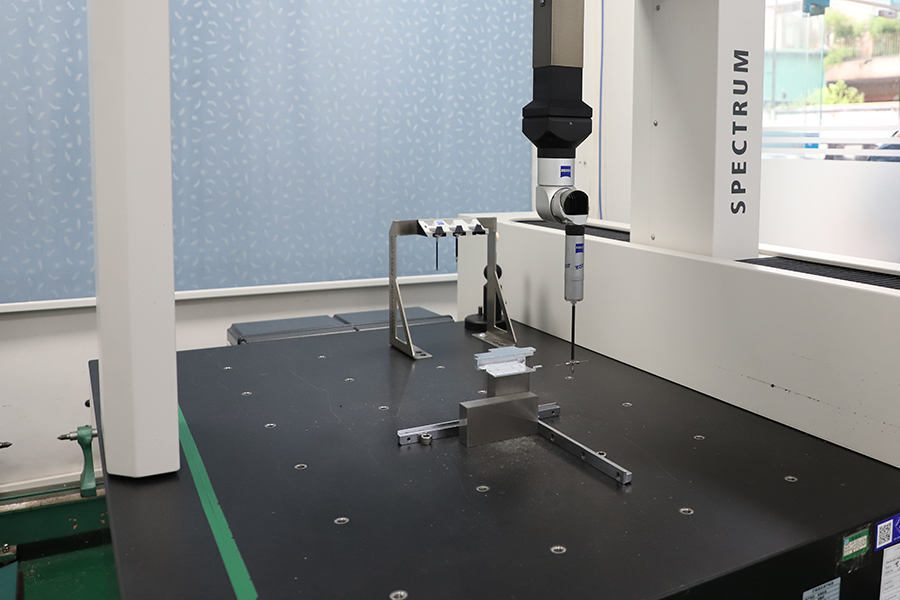

After the completion of production, it is necessary to carry out quality inspection on the parts to ensure that the dimensional accuracy, shape accuracy and surface quality of the parts meet the requirements. Quality inspection can use a variety of testing equipment and methods, such as coordinate measuring instrument, caliper, micrometer and so on.

The process from precision CNC stamping to bending is an important part of automatic machining. Through reasonable design, mold manufacturing, production process control and quality inspection, high quality parts can be produced. In the future, with the continuous development of automated machining technology, this process will be more intelligent, efficient and green, providing more powerful support for the development of various industries.