BACK

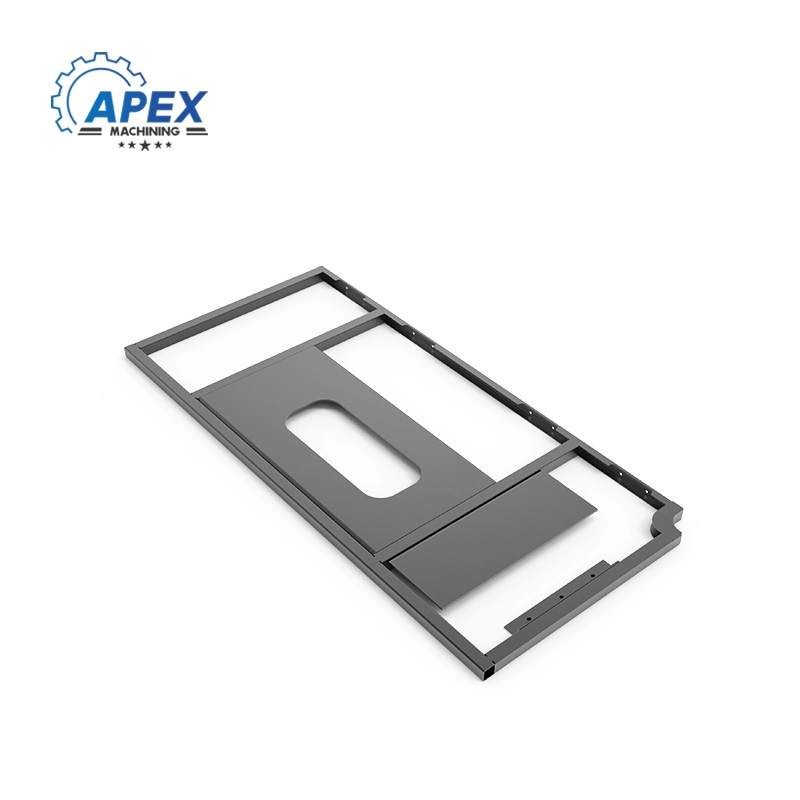

Customized processing of sheet metal parts-car skin

The personalized needs of the automotive manufacturing field are highlighted, we focus on the custom processing of automotive skin, the use of 3D modeling software design, and the selection of high-quality materials. The custom process includes sculpting the skin, using CNC laser cutting and plasma cutting technology. We have experienced technicians, precise control of the mold and stamping equipment, to ensure the precision and beautiful molding process.

In the field of automobile manufacturing, personalized demand is becoming increasingly prominent, we focus on the production of auto skin in the customized processing of sheet metal parts, with professional and exquisite technology, for each customer to create a unique auto skin.

Deep communication, exclusive custom design

The starting point of custom processing is in-depth communication with customers. Our professional team will understand in detail the unique needs of customers for automotive skin, whether it is the pursuit of extreme personalized appearance, or structural optimization for specific functions, all listen carefully. Then, advanced 3D modeling software is used to translate the customer's ideas into precise design drawings. In the design process, full consideration is given to the overall performance of the car, the principle of aerodynamics and the feasibility of actual production, to ensure that the customized design not only meets the personalized demands of customers, but also meets the high standards of the automotive industry.

Select materials to meet custom needs

Based on custom design solutions, we carefully select suitable materials. If the customer is looking for lightweight and stylish appearance, high-quality aluminum alloy sheet is the best choice, its lightweight texture can effectively reduce the weight of the body, improve fuel economy, excellent surface quality lays a good foundation for the subsequent painting process. For custom requirements that emphasize strength and durability, high-strength alloy steel is the first choice, providing reliable protection for automotive skin in complex road conditions and harsh environments. Each material is carefully screened to ensure that its performance indicators meet the specific requirements of customized automotive skin.

Custom craft, sculpted perfect skin

We are committed to providing customers with high-quality and personalized automotive skin sheet metal parts through the careful carving of each custom processing link, helping automobile manufacturers to create more personalized charm and market competitiveness of automotive products.