BACK

Fine Products of Metal Stamping and Molding Industry

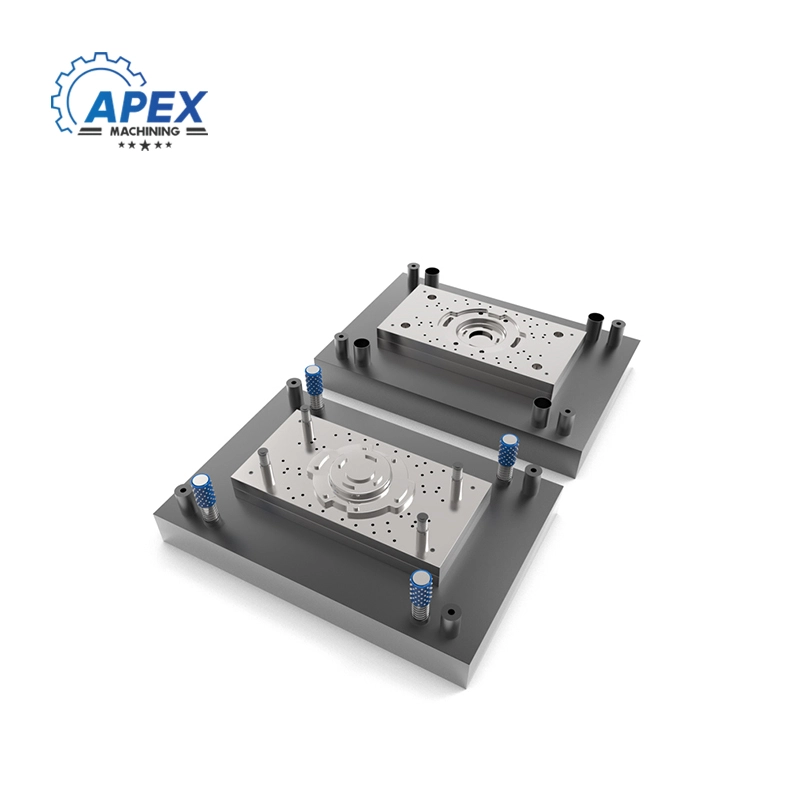

Metal stamping molds are made of strong alloy materials, with upper and lower molds working together, efficient and accurate stamping, helping the industry to accurately shape, improve production efficiency and reduce costs.

Regarding mold components, metal stamping dies are like a talented artisan. It is rather important in various industrial production linkages because of its outstanding performance and special workmanship.

Key instruments for acquiring components of the intended shape and size are metal stamping dies, which position metal sheets between dies and apply pressure to make the sheets plasticly deformed. Usually including an upper and a lower die, its structural design is rather complicated. The bottom die is fastened on the worktop of the press; the higher die is positioned on its slide. High-strength, high-hardness, extremely wear-resistant alloy steel makes up the mold's operating elements—the punch and die, for example. These materials guarantee that the mold maintains correct form and dimensional precision after long-term usage by resisting great stamping pressure and frequent friction.

Metal stamping dies demonstrate incredible accuracy and efficiency in the stamping process. From basic circles and squares to exact automobile components, electrical device housings, etc., it can rapidly stamp metal sheets into numerous complicated designs. In the automobile production sector, for instance, metal stamping dies may print steel plates into body frames, doors, hoods and other pieces, which are not only very complicated in form but also have rather high dimensional accuracy and surface quality standards. Metal stamping dies assure that every stamped component satisfies high quality criteria by means of their exact design and production technique, therefore assuring the general performance and safety of the automobile.

Good adaptability and reproducibility of metal stamping dies represent their benefits as well. Replacing multiple molds allows components of various specifications and forms to be created after the mold design and manufacturing are finished, therefore considerably increasing production efficiency and flexibility. Furthermore, tens of thousands of times or even more may be utilized from a well maintained mold, so metal stamping dies are rather affordable in mass manufacturing.

Besides, metal stamping dies are always evolving and inventing as contemporary manufacturing's ongoing development of product quality and production efficiency criteria calls for. Metal stamping die design and manufacture make extensive use of advanced mold design tools and production technologies like computer-aided design (CAD), computer-aided manufacturing (CAM), CNC machining, etc. These technologies enable quicker production cycles, more rational and exact mold design, and improved quality by means of their implementation. Simultaneously, the degree of molds' automation is also always rising. Using waste discharge systems and automated feeding devices, for instance, has helped to further lower labor costs and increase production efficiency.

With their exact construction, effective stamping performance, high adaptability and repeatability, and continual creative technological applications, metal stamping molds have become a vital shaping tool in contemporary industrial manufacture as a major component of mold parts. It has made great contributions to advancing the manufacturing sector and finds extensive uses in numerous sectors like electronics, aircraft, etc., including cars.