BACK

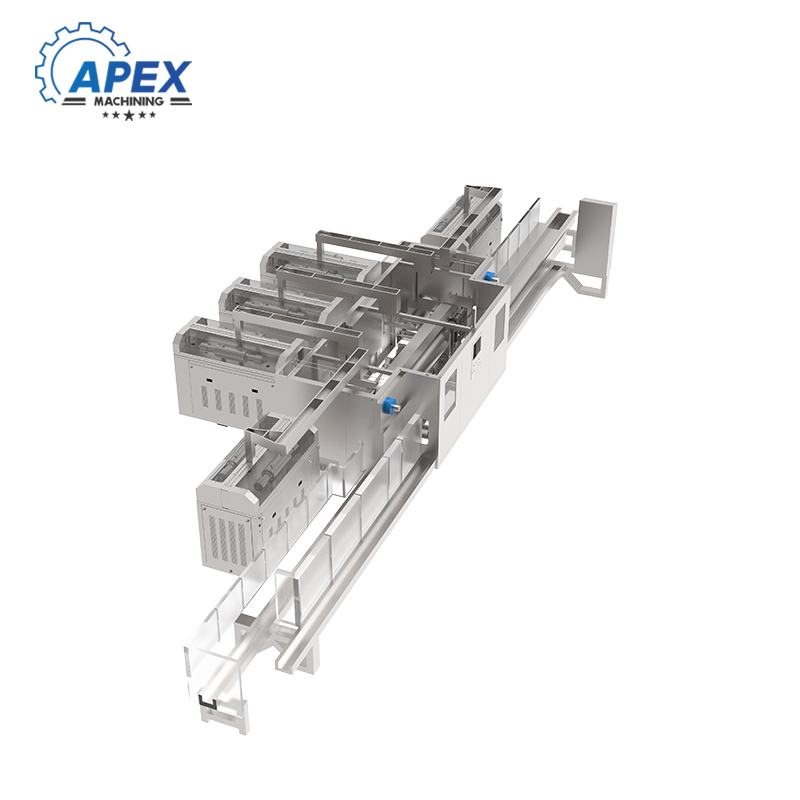

High-Pressure Autoclave

The ultra-high pressure sterilization machine plays a key role in cell culture. It uses ultra-high pressure technology and gentle sterilization process to protect biological activity and provide efficient aseptic processing solutions. Modular design, multiple chamber specifications and pressure level configurations meet the needs of different scenarios. Chamber materials, safety design, and compliance design ensure production bottom line.

Ultra-High Pressure Sterilization Integrated Machine: The Sterile Foundation for Precision Cell Culture

In the meticulous operations of cell culture, the ultra-high pressure sterilization integrated machine serves as a critical sterilization device, providing efficient and reliable aseptic processing solutions for culture media, experimental consumables, and biological products. Through innovative ultra-high pressure technology and gentle sterilization processes, this equipment eliminates microorganisms while protecting the activity of biological components, acting as a vital link between upstream cell culture preparation and downstream experiments to enhance the success rate of cell culture and product quality.

1. Revolutionary Application of Ultra-High Pressure Sterilization Technology

The ultra-high pressure sterilization integrated machine employs the principle of hydrostatic pressure transmission, applying uniform pressure to materials within a sealed chamber to disrupt microbial cell membranes and genetic material, achieving log-level sterilization effects. Unlike traditional high-temperature sterilization, which risks thermal damage, this physical sterilization method operates at room or low temperatures, effectively preventing denaturation of heat-sensitive components in culture media—such as growth factors and amino acids—thereby safeguarding the viability of sensitive cells like stem cells and primary cells. The biocompatible chamber materials can withstand high-pressure environments without chemical reactions with materials, ensuring the safety and purity of the sterilization process.

2. Modular Design for Diverse Scenario Adaptation

The equipment offers multiple chamber specifications and pressure grade configurations, suitable for small-batch consumable sterilization in laboratories (e.g., petri dishes, pipettes) to industrial-scale whole-bag culture medium processing. Detachable sterilization baskets and quick-install sealing components enable flexible loading of different material types, reducing operation time. For special samples in cell therapy, such as viral vectors and cell cryopreservation solutions, the equipment can preset low-pressure protection programs to maintain sample structural integrity during sterilization, meeting the stringent requirements of precision medicine. The intelligent control system supports customizable programming of sterilization protocols, automatically recording key parameters like pressure, time, and temperature to ensure consistent batch-to-batch processing effects.

3. Compliant Safety Design Safeguarding Production Standards

Chambers and contact components are constructed from 316L stainless steel or food-grade engineering plastic, with surfaces electropolished to meet cGMP hygiene requirements for pharmaceutical equipment. Multiple pressure sensors and leakage monitoring devices provide real-time feedback on operational status, triggering automatic pressure relief and audible-visual alarms in case of anomalies to prevent overpressure risks. The equipment supports full-process sterilization validation, equipped with biological indicator placement sites and data traceability functions to provide a complete audit trail for cell culture quality control, complying with international standards such as GLP and ISO 13485 for aseptic processing. Its low-vibration and silent operation design adapts to environmental standards in clean laboratories and GMP workshops, enhancing the user experience.

4. The Aseptic Cornerstone for the Entire Cell Culture Process

In the cell culture system, the ultra-high pressure sterilization integrated machine plays a pivotal role as a "safety barrier":

Pre-Experiment Sterilization: It sterilizes culture media and sera before experiments.

In-Experiment Preparation: It ensures aseptic readiness of glassware and instruments during experiments.

Post-Experiment Treatment: It inactivates waste safely after experiments.

Through efficient and gentle sterilization processes, the equipment eliminates exogenous microbial contamination that could cause cell pollution or culture failure. Its low-temperature sterilization feature is particularly suitable for media containing animal-derived components or bioactive factors, avoiding high-temperature damage to nutrients and providing an ideal aseptic environment for cell adhesion, growth, and differentiation. The compact layout and user-friendly interface further enhance laboratory and production line efficiency, reducing manual intervention errors.

The ultra-high pressure sterilization integrated machine, with its innovative sterilization technology, modular design, and compliant safety architecture, has become a core equipment for aseptic assurance in cell culture. It precisely balances sterilization efficacy and bioactivity protection, providing reliable support for sensitive cell culture and enabling technological breakthroughs in 前沿 fields (cutting-edge fields) such as stem cell research and cell therapy for research institutions and biopharmaceutical enterprises. Whether in basic laboratory research or large-scale industrial cell expansion, this equipment serves as an indispensable aseptic processing partner in cell culture workflows with its stable performance and professional design, driving the standardized development of life science research and applications.