Datetime:2025-08-09

As the manufacturing industry continues to demand ever-increasing precision and efficiency for complex parts, multi-axis CNC technology has become a core tool for achieving efficient precision machining. This technology, by controlling the coordinated motion of multiple machine tool axes, overcomes the challenges traditional machining methods face when processing irregularly shaped parts and complex curved surfaces. Whether it's processing irregularly shaped parts or curved parts requiring the highest surface quality, multi-axis CNC significantly improves machining freedom and accuracy. This technology's application value is particularly evident in fields such as aerospace, where component reliability and precision are crucial. This article will delve into the working principles of multi-axis CNC, analyze its unique advantages in machining irregularly shaped parts and curved surfaces, and reveal how it drives an overall leap in precision manufacturing efficiency.

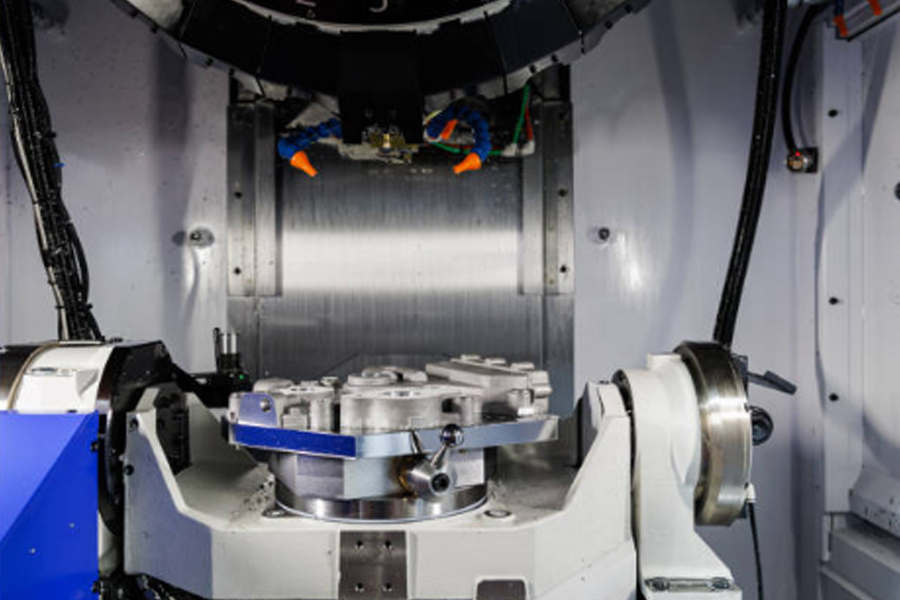

Understanding Multi-Axis CNC Technology

Multi-axis CNC technology is the core driving force of modern precision machining. It transcends the limitations of traditional machine tools by precisely synchronizing and coordinating multiple motion axes under computer control. Key to this technology is the machine tool's ability to simultaneously control multiple motion axes (such as the X, Y, and Z linear axes, as well as the A, B, and C rotary axes) to perform complex spatial motion. This means the tool can continuously approach the workpiece from multiple directions. This is particularly true for machining special-shaped parts with complex curves, deep cavities, or unusual angles. Multi-axis linkage significantly reduces clamping times and avoids the cumulative errors caused by repeated positioning. Its advantage lies in the ability to efficiently and accurately complete the cutting of complex geometries in a single clamping setup, significantly improving the efficiency and quality of curved surface machining. This is particularly applicable to the demanding requirements of the aerospace industry for high-precision, high-reliability components.

Surface Machining Methods for Special-Shaped Parts

Compared to traditional three-axis CNC machine tools, multi-axis linkage technology brings revolutionary improvements in efficiency and precision to the machining of complex, special-shaped and curved parts. Its core principle lies in the precise, synchronized and coordinated movement of the machine's multiple motion axes (such as the X, Y, and Z axes plus the rotating A, B, or C axes) according to pre-programmed instructions. This enables the tool to consistently engage the complex workpiece's curved contours at the optimal angle, a significant advantage when machining aerospace components with complex curved surfaces or deep cavities, such as impellers, turbine disks, and engine blades. Using CNC machines with five or even higher axes, coupled with precise tool axis vector control strategies, complex surface milling, which previously required multiple setups and multiple steps, can be accomplished in a single operation. This ensures smooth and continuous surface transitions, significantly reduces the need for manual finishing or secondary machining, and significantly shortens machining cycles. Furthermore, this machining method effectively controls tool vibration and improves cutting stability, resulting in higher surface quality and dimensional accuracy (machining accuracy can reach ±0.01 mm) and effectively reduces the risk of deformation during machining of thin-walled structural parts. This has been fully demonstrated in the machining of high-rigidity, lightweight aerospace components.

Aerospace Precision Case Studies

The aerospace industry places extremely stringent demands on component accuracy and reliability, a perfect opportunity for multi-axis CNC technology to demonstrate its capabilities. For example, in the manufacture of complex turbine disks, a key component of aerospace engines, faced with the challenges of high-temperature alloy materials and high-precision curved contours, traditional machining methods are inefficient and difficult to ensure quality. Airy Precision Company uses an advanced five-axis machining center, which can complete the machining of multiple special-shaped surfaces and precision hole systems on turbine disks in a single setup. This process not only significantly shortens production cycles but, more importantly, maintains stable precision of critical dimensions within ±0.005mm, fully meeting the stringent aerospace standards for zero defects and high reliability. The process manager noted that this technical approach effectively addresses the challenge of deformation control in the machining of complex, irregularly shaped parts, ensuring stable product performance in extreme environments.

Through practical application by Airei Precision in the aerospace industry, multi-axis CNC technology has significantly improved the accuracy and efficiency of irregular and curved surface machining, achieving reliable, high-quality output. This precision machining method not only shortens production cycles but also reduces the risk of manual intervention, providing stable support for the manufacture of complex parts. In the future, as the technology continues to improve, multi-axis CNC will play a key role in more high-end fields, driving a leap forward in overall manufacturing standards.