Datetime:2025-10-17

Determining die-casting tolerances requires comprehensive consideration of multiple factors, including design requirements, material properties, and processing equipment capabilities. Design requirements define the product's function and structure, ensuring effective fit between components through appropriate tolerance settings. Material properties, such as thermal expansion and strength, directly impact the performance of die-cast parts during processing and use. Therefore, a thorough evaluation of the various material properties can help develop more targeted tolerances. Finally, the capabilities of the processing equipment are also crucial. Advanced equipment allows for tighter tolerances, while insufficient equipment limits precision. Understanding the relationship between these factors enables companies to achieve efficient and economical production processes while ensuring product quality.

Analysis of Key Factors in Die-Casting Tolerance Setting

In die-casting, tolerance setting is fundamental to ensuring the expected quality of products. First, design requirements directly influence the tolerance range. The dimensional and shape requirements in the design drawings determine the appropriate tolerance values, ensuring proper assembly and function of the part. Second, material properties are equally important. Physical properties of different materials, such as thermal expansion and strength, affect the stability of the part during processing and use. Therefore, when setting tolerances, a reasonable assessment based on specific material data is necessary. Furthermore, the performance of the processing equipment is also a crucial factor. High-precision equipment can achieve tighter tolerances, while insufficient equipment capacity limits the range that can be set. Comprehensively considering these key factors can help companies find the optimal balance between ensuring product quality and performance.

The Relationship Between Design Requirements and Tolerances for Improving Die-Casting Quality

In the die-casting process, design requirements and tolerance setting are closely related. First, designers must understand the product's functional requirements in order to determine an appropriate tolerance range. Too wide a tolerance may affect part fit accuracy, while too narrow a tolerance may increase production costs. Therefore, a thorough assessment of material properties and processing methods during the design phase is fundamental to establishing effective tolerances. Second, various mechanical components require different precision during assembly, which directly impacts final product quality. For example, some critical dimensions require tighter tolerances, while less critical dimensions can be more relaxed. Furthermore, good communication and collaboration ensure alignment between design and processing teams on goals and standards, thereby improving product consistency and reliability. The Critical Impact of Material Properties on Die Casting Tolerances.

In die casting, material properties play a crucial role in setting tolerances. Different metals, such as aluminum, magnesium, or zinc alloys, have varying coefficients of thermal expansion, fluidity, and hardness. These properties directly influence the deformation and shrinkage of the casting during cooling. Therefore, tolerances must be tailored to the specific properties of the selected material. For example, aluminum alloys can experience relatively significant shrinkage upon cooling, requiring wider design tolerances to avoid defects in the finished product. Furthermore, some materials exhibit improved fluidity at high temperatures, which not only improves die casting accuracy but also allows for more relaxed tolerances in certain areas. Therefore, understanding and applying these material properties when designing die castings can effectively improve product quality and reliability while ensuring efficient production processes.

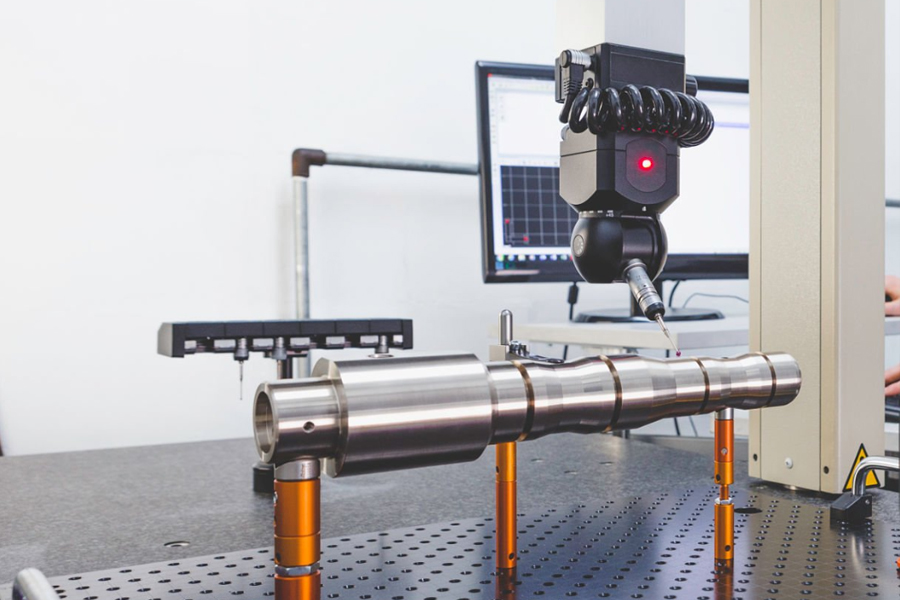

The Role of Processing Equipment Performance in Tolerance Setting: A Case Study

In die casting, processing equipment performance directly influences tolerance setting. High-precision equipment can produce qualified products within tighter tolerances. For example, modern CNC die-casting machines achieve relatively tight tolerances by precisely controlling temperature and pressure. However, insufficient or unstable equipment performance can lead to structural and dimensional inconsistencies in the product. Therefore, when determining tolerances, the equipment's actual capabilities must be considered. By monitoring actual production of a specific die-casting machine model, tolerance standards tailored to its performance characteristics can be established, ensuring that every part meets design requirements. This approach not only improves product consistency but also effectively reduces production costs.

Die-casting process tolerances involve multiple key factors, all of which are interconnected and have a profound impact on the quality and performance of the final product. Design requirements provide the foundation for ensuring the product's functional efficiency. Material properties, meanwhile, help manufacturers understand the tolerances that best suit the properties of different materials and prevent potential problems during processing. Processing equipment performance is a crucial factor in determining the achievable tolerance range and accuracy. The more sophisticated the equipment, the tighter the tolerance range. By comprehensively considering these factors and making appropriate adjustments, companies can achieve efficient production and cost control while ensuring part quality. Therefore, in actual operation, all parties need to work closely together to ensure the best tolerance setting to promote the smooth progress of the entire die-casting process.