BACK

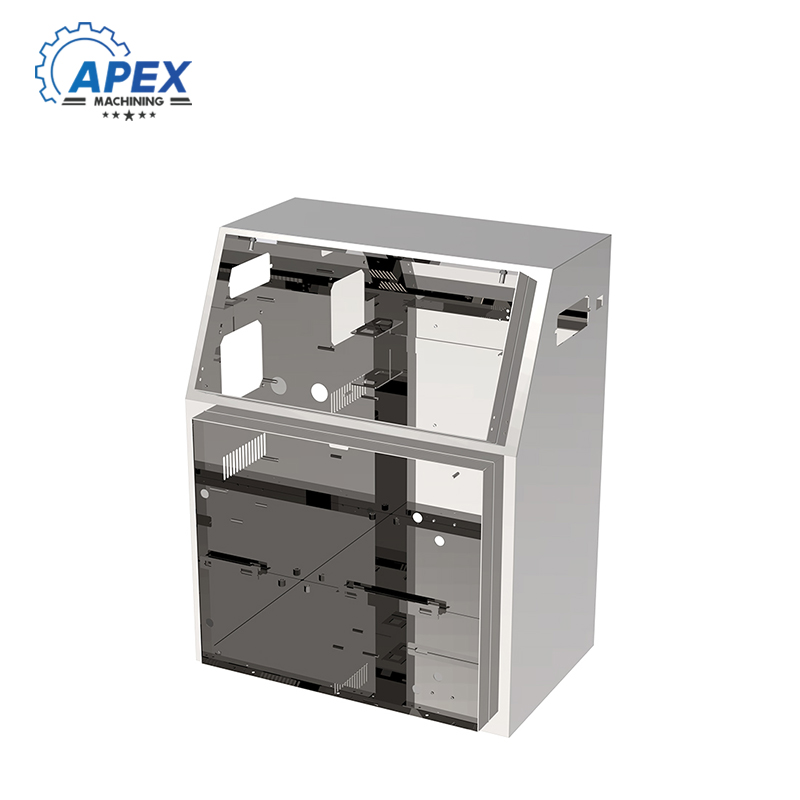

Inkjet printer housing

The shell of the printer is the core bearing component of the equipment. Through structural design and material application optimization, it provides systematic guarantee for the stable operation of the equipment. Product function and design positioning The shell of the printer is the structural carrier of the integrated equipment hardware system. It adopts a modular design concept and organically combines mechanical protection, human-computer interaction, heat dissipation management and other functions.

In the field of industrial identification equipment, the shell of the inkjet printer, as the core bearing component of the equipment, not only bears the physical protection function, but also provides systematic guarantee for the stable operation of the equipment through the optimization of structural design and material application. This article comprehensively analyzes the core value of the shell of the inkjet printer from the dimensions of product positioning, functional characteristics, application scenarios, technical advantages and manufacturing processes.

Product Function and Design Positioning

The shell of the inkjet printer is a structural carrier of the integrated equipment hardware system. It adopts a modular design concept to organically combine mechanical protection, human-computer interaction, heat dissipation management and other functions. Its core functions include:

● Physical protection: resist damage to internal circuits, nozzles, and control systems from external impacts, dust, liquids and other environmental factors;

● Heat dissipation management: optimize the air circulation path through structural design, and cooperate with heat dissipation components to achieve balanced heat distribution;

● Operation adaptation: reserve the operation interface, interface module and maintenance space to improve the convenience of human-computer interaction;

● Electromagnetic shielding: reduce the impact of external electromagnetic interference on equipment signal transmission and ensure the stability of inkjet coding accuracy.

Adaptation to multiple application scenarios

The design of the printer shell fully considers the differentiated needs of different industries to form a multi-scenario adaptation solution:

1. Food and pharmaceutical industry

● Demand characteristics: It needs to meet the clean production environment, be corrosion-resistant and easy to clean, and avoid material precipitation and contamination of products.

● Shell solution: Food-grade engineering plastics or stainless steel are used, the surface is smoothed, and the joints are designed with a waterproof and dustproof sealing structure to adapt to the frequent disinfection scenarios in high-speed operation of the assembly line.

2. Electronics and 3C manufacturing

● Demand characteristics: High requirements for electromagnetic compatibility, need to adapt to the micro-environment control of precision inkjet printing, and prevent electrostatic interference.

● Shell solution: Integrated metal shielding layer and anti-static coating, the internal structure reserves a precision guide rail installation position to ensure the stability of the nozzle movement and adapt to the high-precision requirements of tiny character inkjet printing.

3. Packaging and logistics industry

● Demand characteristics: The equipment needs to adapt to high-frequency outdoor movement, cope with complex working conditions such as temperature difference and vibration, and ensure long-term continuous operation.

● Shell solution: adopt high-strength alloy frame and anti-seismic buffer design, wear-resistant coating on the surface, and internal structure to strengthen the heat dissipation module to meet the heat dissipation requirements of 24-hour uninterrupted inkjet printing.

4. Industrial manufacturing production line

● Demand characteristics: need to be integrated with automated production lines, support multi-angle installation, and be compatible with robotic arm grabbing or fixed station deployment.

● Shell solution: adopt standardized interface design, reserve sensor installation positions and cable channels, and the structure takes into account both lightweight and rigidity, adapting to rapid integration of production lines and equipment upgrades. 3. Core technical advantages

As the "physical center" of the equipment, the design and manufacturing level of the inkjet printer shell directly affects the service life, operating stability and scene adaptation capabilities of the inkjet printer. Through material innovation, structural optimization and process upgrades, this product not only provides reliable equipment protection solutions for industries such as food, medicine, electronics, and logistics, but also helps equipment manufacturers improve production efficiency and reduce later maintenance costs through standardized and modular design. Under the trend of industrial automation and intelligence, the casing of inkjet printers is gradually upgraded from a single protective carrier to a systematic solution integrating functional integration and scene adaptation, promoting the development of the marking equipment industry towards efficient, reliable and diversified applications.