BACK

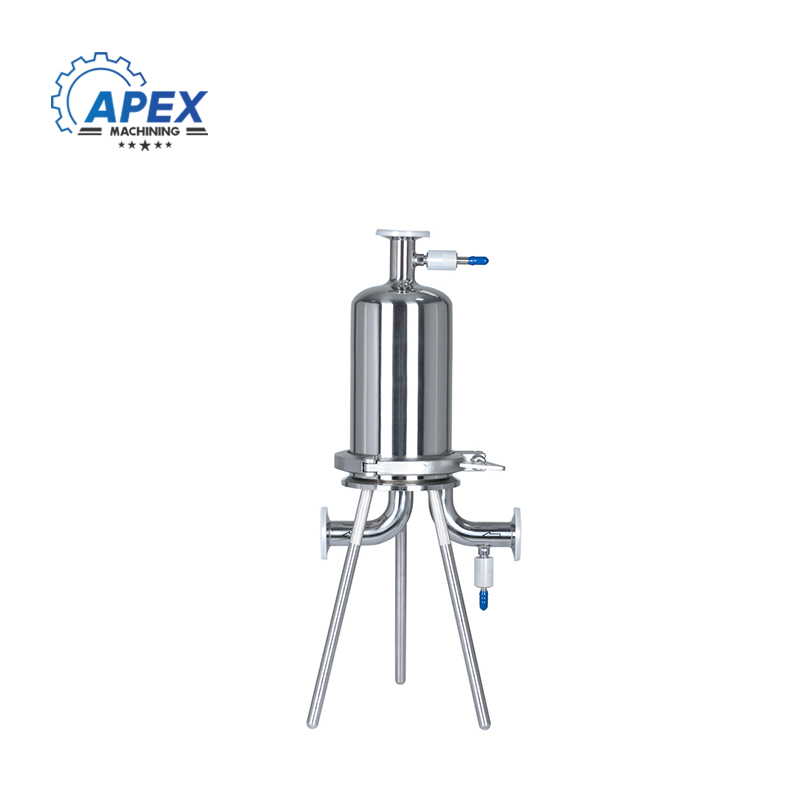

Medical Equipment Filter Housings

The medical equipment filter housing is made of stainless steel or food-grade polypropylene, with a fully enclosed streamlined design and a precise structure to optimize filtration efficiency. Compliant manufacturing meets stringent standards and complies with international specifications such as cGMP, ASME BPE, etc. All components are biocompatible and free of defects such as cracks and pores. Real-time monitoring and abnormal confirmation of the filtration process.

In the High-Purity Production Environment of Biopharmaceuticals: The Medical Device Filter Housing as a Core Component of Filtration Systems

Within the stringent clean production environments of biopharmaceuticals, the medical device filter housing serves as the core load-bearing component of filtration systems, playing a critical role in protecting filter media, maintaining aseptic conditions, and ensuring safe fluid transportation. Through the selection of biocompatible materials, precise structural design, and compliant manufacturing processes, this housing provides reliable barrier protection for the production of biological products such as antibody drugs, vaccines, and recombinant proteins, ensuring the efficiency and safety of filtration processes.

Biocompatible Materials Building a Safety Barrier

The main body of the filter housing is constructed from 316L stainless steel or food-grade polypropylene (PP), with surfaces undergoing electro polishing or supercritical cleaning to meet biosecurity-level cleanliness standards. These materials exhibit excellent corrosion resistance, withstanding the acidic/alkaline solutions and high-temperature steam used in Clean-in-Place (CIP)/Sterilize-in-Place (SIP) processes to prevent contamination of liquids from metal ion leaching or material aging. The inner wall smoothness complies with the strict surface roughness requirements of GMP, minimizing risks of protein adsorption and microbial growth—thereby providing a stable operating environment for filter media and safeguarding the purity and safety of biological products.

Precise Structural Design Optimizing Filtration Performance

The housing features a fully enclosed streamlined design with sanitary quick-connect interfaces (e.g., clamp-type, flange-type), ensuring airtight and convenient pipeline connections to prevent external contaminant intrusion. Internal flow-guiding structures are optimized via fluid dynamics to reduce fluid dead zones and pressure loss, enhancing the stability of filtration flux. The detachable cartridge chamber supports single or multi-cartridge configurations, enabling flexible switching between different filtration precisions (e.g., prefiltration, terminal sterilization filtration) through modular design—adapting to diverse scenarios in biopharmaceuticals such as culture medium sterilization, virus removal, and protein solution clarification. Elastic sealing components work in tandem with pressure balance devices to effectively handle pressure differential fluctuations during filtration, preventing cartridge displacement or leakage and ensuring process continuity.

Compliant Manufacturing Meeting Stringent Standards

Production of the filter housing strictly adheres to international norms such ascampP and ASME BPE, with all material-contact components certified for biocompatibility under USP Class VI and FDA 21 CFR Part 11. Welding processes utilize automatic orbital welding, and welds undergo dye penetrant testing and endoscopic inspection to ensure no defects such as cracks or pores, eliminating potential contamination risks. The equipment supports full-process cleaning validation and sterilization confirmation, integrated with pressure sensors and leakage detection modules for real-time filtration monitoring and anomaly alerts—providing reliable data support for the quality traceability system in biopharmaceuticals.

A Reliable Protective Partner Across Diverse Scenarios

In biopharmaceutical production lines, the filter housing acts as a key node connecting upstream cultivation and downstream purification: whether for prefiltration of cell culture media before reactor entry or terminal sterilization filtration of finished liquids before filling, it ensures efficient operation of the filtration system through stable structural performance and safety design. Its impact resistance and high-pressure tolerance make it suitable for complex process conditions involving high-viscosity fluids or particulate impurities, reducing production disruptions caused by equipment failures. The lightweight design and compact layout adapt to space constraints in clean rooms, enhancing the overall coordination of the production line.

The medical device filter housing—characterized by biocompatible materials, precise structural design, and compliant manufacturing—has become indispensable protective equipment in biopharmaceutical clean processes. Focused on the core needs of filtration systems, it balances media protection, aseptic environment maintenance, and fluid efficiency optimization, providing a solid foundation for producing biological products like antibodies and vaccines. Whether for small-scale R&D filtration or large-scale industrial purification, this housing supports enterprises in maintaining quality standards and improving production efficiency with its reliable performance, establishing itself as a trusted process partner in the biopharmaceutical equipment sector.