BACK

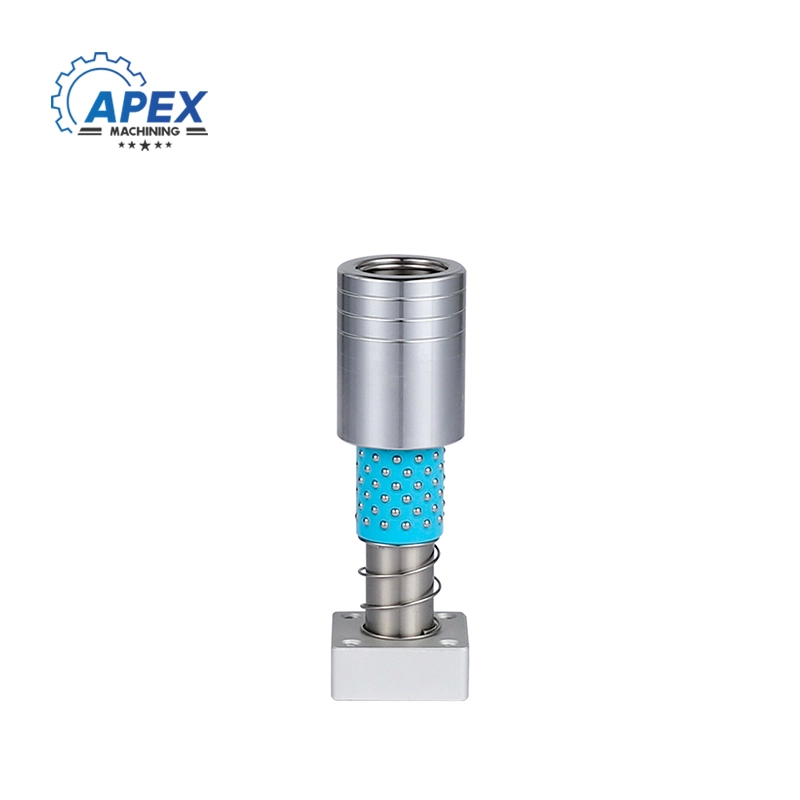

Mold Guide Pillar Bushings Protect Mold Precision Operation

Mold guide pillar bushings, high-quality materials, wear resistance, precision clearance, long-term lubricity, stable protection for precise mold operation.

Usually composed of premium wear-resistant materials such either special copper alloy or high-hardness alloy steel, the mold guide pin bushing is This material choice allows it great wear resistance and fatigue resistance as well as withstands the repeated friction and impact between the guide pin and the bushing during the frequent mold opening and closure. Every working cycle of the mold, the guide pin travels exactly along the bushing's inner wall. The high-quality material guarantees that this sliding operation is smooth and seamless, thus efficiently lowering the metal waste produced by wear and preventing it from injuring other precision elements within the mold, so preserving the general cleanliness and accuracy of the mold.

From a structural design standpoint, the mold guide pin bushing maintains a stringent clearance fit with the guide pin and has quite high dimensional accuracy. The complexity of its design is this little and exact gap. It will not cause the mold to wobble or dislocate owing to too high clearance, thus compromising the molding quality of the product. It can supply the guide pin with exactly the proper guiding effect to guarantee that the top and lower molds of the mold are precisely aligned throughout the mold closure process. For instance, creating plastic items with exact dimensions and beautiful appearance depends on exact mold sealing in plastic injection molds. Like a precise ruler, the mold guide pin bushing guides the many sections of the mold to cooperate, thus distributing the plastic melt in the mold cavity, and lastly producing a product that satisfies the design criteria.

The mold guide pin bushing likewise offers superior lubrication performance throughout long-term mold usage. Usually including a unique lubrication channel or oil storage tank, its inner wall may store the necessary quantity of lubricating oil and automatically create a consistent oil film upon sliding of the guiding pin. This oil layer lowers energy loss, helps to disperse heat, thus preventing too high component temperature resulting from frictional heat production and so influences mold performance by reducing the friction coefficient between the guide pin and the bushing. Furthermore, extending the service life of the mold guide pin bushing, lowering the maintenance frequency and cost of the mold, and enhancing production efficiency is excellent lubrication performance.

Closely related and working with other mold elements, the mold guide pin bushing It works with the guide pin to provide the opening and closing action of the mold steady guiding support; the connection with the template is strong and consistent to guarantee that it will not loosen or distort when exposed to a strong clamping pressure. Although the mold guide bushing is modest in the whole mold system, it is like a key screw preserving the regular mold operation order. Once a failure or excessive wear takes place, it will immediately influence the accuracy, manufacturing efficiency, even product quality of the mold.

Because of its high-quality materials, exact structural design, superior lubrication performance, and tight interaction with other parts, the mold guide bushing has evolved into a necessary component of the mold parts family. It is a solid promise for the long life of the mold and great precise operation. In the fields of mold manufacture and industrial production, it is indispensable; it also facilitates the effective and high-quality molding of different goods.