Datetime:2024-12-23

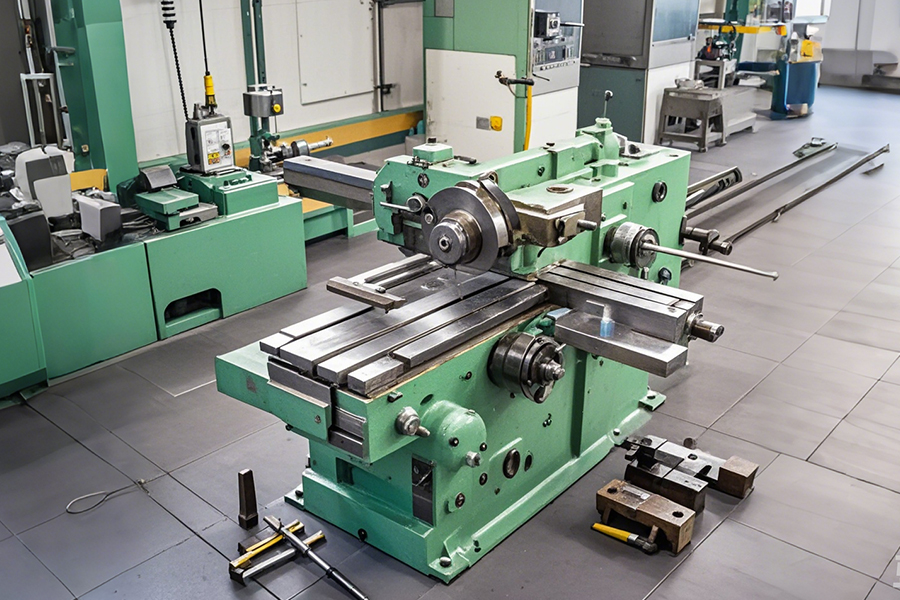

Planing is a brilliant yet distinctive pearl in the large area of digital controlled mechanical processing that is very essential for mechanical production.

Guarantor of very precise processing

With its own processing technique, planing has opened mechanical production great opportunities for high accuracy. In the sphere of life sciences, planning is absolutely inseparable with the manufacturing of numerous precision equipment. For biological sample examination, for instance, the high-precision microscope stage has rather stringent flatness criteria. Planing guarantees the flatness and straightness of the stage surface, so enabling the microscope to provide a stable and accurate platform when viewing the sample, and provides consistent data support for life science research by precisely removing materials through the relative linear motion of the tool and the workpiece. Certain sensors in the intelligent sector also depend on very precise processing based on their shells and internal architecture. Planing guarantees the dimensional correctness of these components, therefore enabling more precise sensor sensing and transmission of information.

Shaper of intricate designs

In forming intricate forms, planning offers special benefits. In the automobile industry, planing may be used to process the plane of the cylinder and certain unique forms of grooves in the processing of complicated elements including engine cylinders. By changing the movement pathways of tools and workpieces in line with design criteria, it may create intricate constructions that satisfy the high-performance operation of automotive engines. Planing can precisely process the necessary shape for specific automotive components with unique needs, including the mounting surface of high-performance brake discs, thereby guaranteeing the stability and dependability of the braking system. Intelligent industry's automated production line equipment also has a lot of differently shaped components that must be handled. Planing guarantees the seamless running of the manufacturing line and can satisfy the processing requirements of these complicated forms.

The realization of material adaptation

Of enormous importance in mechanical production, planing offers a broad spectrum of adaptation to materials. Planing can handle both high-strength, corrosion-resistant materials like titanium alloys often employed in the area of life sciences, or aluminum alloys, alloy steels and other materials utilized in great volumes in the automotive sector. The planing tool may be chosen and changed depending on the properties of various materials to guarantee that, even in case of material removal, the performance of the material will not suffer. Planing, for instance, may finish the processing of the cylinder head surface and internal structure while guaranteeing the strength and sealing of the material, therefore enabling the engine to run properly. Planing may also be very useful in the intelligent sector for the processing of components like electronic component shells of various materials because of its great material adaptability traits.

Cost-effectiveness balancing act

In mechanical production, cost-effectiveness is a consideration; so, planning performs well in this respect. Planing equipment is quite basic and less expensive than certain high-cost processing techniques. By fairly organizing the planning process, the production cost may be lowered in the large-scale manufacturing of car components and guarantee quality. Planing may help to achieve accuracy criteria and lower processing costs in the manufacturing of life science equipment for certain small and medium-sized batches of output. Planing may also balance cost-effectiveness and increase the competitiveness of companies on the basis of achieving complicated forms and accuracy criteria in the fabrication of components for intelligent industry.

Fusion using digital control

Planing is also rapidly incorporated with digital technology in the age of digital control mechanical processes. Planing may get more exact tool path control, processing parameter modification, etc. by means of the CNC system CNC planing machine equipment can effectively and precisely process engine components depending on pre-defined programs on the automobile manufacturing line. Digital controlled planning can provide exact processing of small sizes and complicated forms in the production of life science equipment. This integration in the intelligent industry helps plan to better fit the automated and intelligent production mode and raise production efficiency and quality.

Planing is essentially the guarantee of high-precision processing, the shaper of complicated forms, the embodiment of material adaptability, the balancer of cost-effectiveness, and the integrator with digital control in mechanical manufacture. With its special benefits, planning has made significant contributions to the growth of the mechanical manufacturing sector whether in the sphere of life sciences, intelligent industry or vehicles.