Datetime:2025-08-23

In the medical device manufacturing sector, precision CNC machining has become a core option for medical component production. Its importance stems from its rigorous commitment to ensuring medical device safety. Through precise control at the micron level, this technology ensures component dimensional tolerances meet industry standards, effectively eliminating potential risks. This article will explain how precision CNC machining, as a mandatory standard, safeguards patient health in medical component manufacturing. It will also highlight the critical role of risk control mechanisms, laying the foundation for subsequent discussions.

The Cornerstone of Medical Device Safety

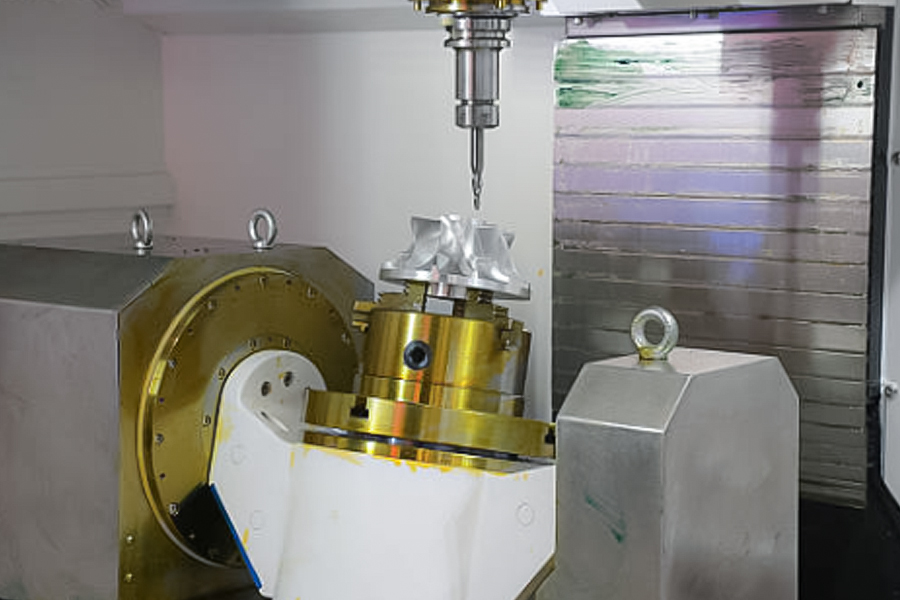

Precision CNC machining technology is a core guarantee for medical component manufacturing, and its importance is directly related to the safety and reliability of the final medical device. When manufacturing critical products such as orthopedic implants, core surgical instrument components, or pacemaker housings, material selection is crucial, but achieving micron-level precision during the machining process is the decisive factor. This means that every hole, every curved surface, and every thread must meet the exacting design tolerances, with no room for deviation. Through precise computer program control and advanced machine tool performance, precision CNC machining ensures absolute dimensional consistency in components, minimizing the risk of device failure due to manufacturing errors at the source and laying an irreplaceable physical foundation for subsequent rigorous sterilization, assembly, and clinical use.

Micron Precision Protects Life

In the manufacturing of medical components, micron-level precision is directly related to the safety and performance of medical devices. Precision CNC machining technology enables micron-level tolerance control, ensuring the precise dimensions of critical components such as implants and surgical instruments. For example, if machining errors exceed one micron in tiny components of artificial joints or heart stents, loosening or failure could occur, posing a threat to patient health. Industry experts emphasize that this precision standard can reduce the risk of failure by over 90%, providing a reliable guarantee for medical device safety. Furthermore, strict tolerance requirements lay the foundation for risk control, eliminating potential hazards.

Required Risk Control Standards

In the manufacturing of medical components that impact patient life and health, risk control is not an option; it is an imperative bottom line. The core reason why precision CNC machining technology has become an industry-recognized must-have standard lies in its comprehensive, quantifiable risk prevention and control system. Through highly automated processes and strict procedural controls, precision CNC minimizes the human error that is inevitable in traditional machining, fundamentally reducing the potential risks associated with dimensional deviations or surface defects. Furthermore, its exceptional repeatability and consistency ensure that every product produced in batches meets the stringent tolerances set, satisfying the pursuit of zero defects for critical components such as implants and surgical instruments. This systematic risk control capability, based on precision manufacturing technology, is an indispensable and robust barrier to ensuring the safety and reliability of medical devices and, ultimately, protecting patients' lives.

The above analysis clearly demonstrates the core value of precision CNC machining in medical component manufacturing. Its micron-level precision not only ensures dimensional consistency across each component but also directly supports the safe operation of medical devices, effectively eliminating potential failure risks. Furthermore, a strict tolerance control system provides a reliable guarantee for risk control, mitigating production risks at the source. This technical standard not only improves manufacturing efficiency but also enhances the reliability of medical devices, ultimately protecting patients' lives and health. Therefore, choosing precision CNC machining is not only an industry norm, but also an inevitable path to achieve safe medical care.